Overview

Fast, compact & productive

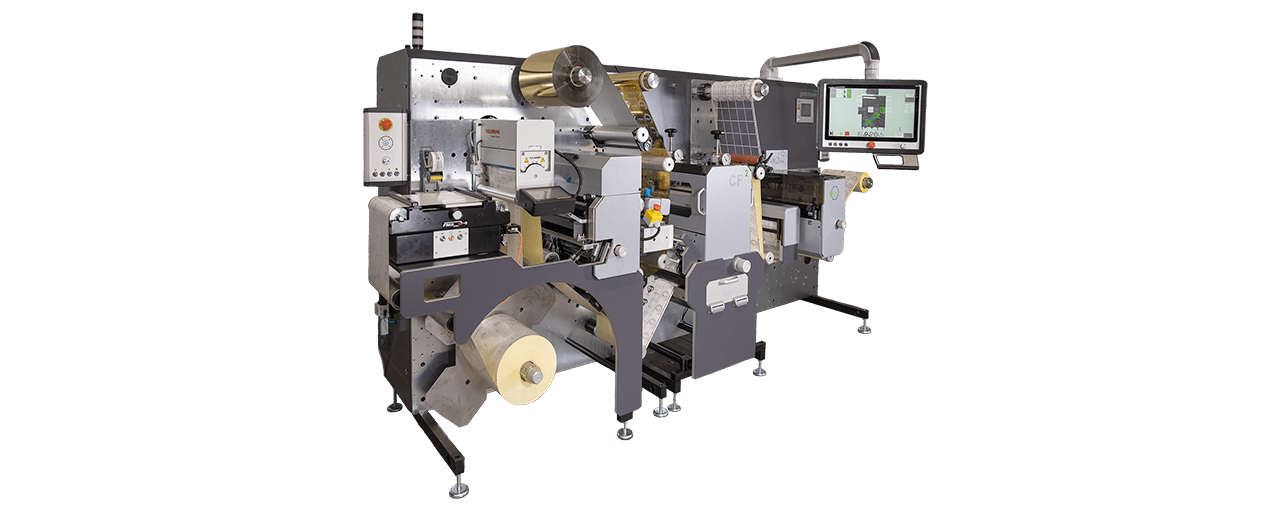

The CF2 Compact Digital Finishing is a fully servo driven machine for finishing of digitally printed labels.

This machine is a compact version of the DCL2 Converting Line. The CF2 incorporates the same high-tech components as the DCL2 with a more compact design. It offers several automated features along with high-speed converting production.

Highlights

- Compact machine, but still high-end and future safe

- Machine built on two modules.

- Built with the same components as the fully modular DCL2 machine.

- The only compact machine that can be extended in the future.

- Upgrade on site with any module in just 8 hours.

- All our future innovations are available for existing customers.

- Innovative, automation features for non-stop production.

Speciality modules and non-stop production features

Non-stop production featuresNon-stop buffer for continuous run Semi-automatic turret AUTOCUT automatic cut at end of roll and start of new cycle. Automatic die loadingQuick and easy change of flexible dies Easy to operate with step by step guide on operator panel Time saving, user friendly solution Flexible die change in 30 seconds |

Sci-fi knivesFastest set up in the industry 1,5 second / knife Up to 15 knives across the web Min slitting width: 15 mm Embellishment modulesHot stamping and embossing from Pantec and Orthotec Flat bed screen printing Rotary Screen module |

AVAILABLE MODULES

Drive systemsLatest servo technology for full web control Machine in solid construction and perfectly balanced Printing modulesModern QC flexo station with no tools needed at change of jobs Spot varnish and overprinting UV/IR Cold foil lamination Second printing module available Slitting modulesShear cut slitting system. The revolutionary SCI-FI KNIVES automatic knife positioning system. Razor blade slitting station Crush cut station. Auto set or manual under/back scorer Rewind unitsSemi-turret: turret for rolls up to 420 mm in turret mode or 600 mm on 1 shaft. AUTOCUT automatic web cutting and start of new cycle. Single & Dual rewind: for label and mono film materials with perfect and automatic tension control for rolls up to 600 mm. |

Intelligent unwind moduleUnwind unit 750 mm capacity with fixed unwind shaft Latest electronic web guide with ultrasonic sensor Adjustable splice table and integrated pneumatic web clamps Die cutting modulesNew generation semi-rotary die cutting system. Q-FLEX Automatic flexible die loading system Compensation program for flexible dies semi-rotary die cutting. Contact matrix waste rewind (snowball type) incl. back score unit. K+B GapMaster with pressure control and oiling system Speed upgrade of semi rotary die cutting to max 70 m/min. Rewind shaftsWith the new Q-SHAFT you turn 1 handle 180o to change the shaft Q-SHAFT is quick, easy and hassle free. |

Technical specifications

Min. web width: 105 mm / 135 mm

Max. web width: 350 mm / 450 mm

Substrate thickness: 100-250 gsm (self adhesive) / 30-150 mic (films)

Max. mechanical speed: up to 70 m/min

Max. unwind roll diameter: 750 mm

Unwind shaft size: 76 mm [3″]

Max. printing width: 350 mm / 450 mm

Max. printing speed: up to 160 m/min

Max. printing speed semi-rotary: 60 m/min

Max. speed lamination: 40 m/min

Lamination roll size: 450 mm

Speed cold stamping: up to 70 m/min